Preparing for Industry 5.0: The Digital Infrastructure Revolution

As we stand on the brink of Industry 5.0, a significant shift is occurring in the landscape of business and technology. The evolution of digital infrastructure is essential for organizations to not only survive but thrive in this new era. This article delves into the transformative technologies set to redefine productivity and innovation, providing a comprehensive overview of what businesses need to consider as they prepare for Industry 5.0.

Understanding Industry 5.0

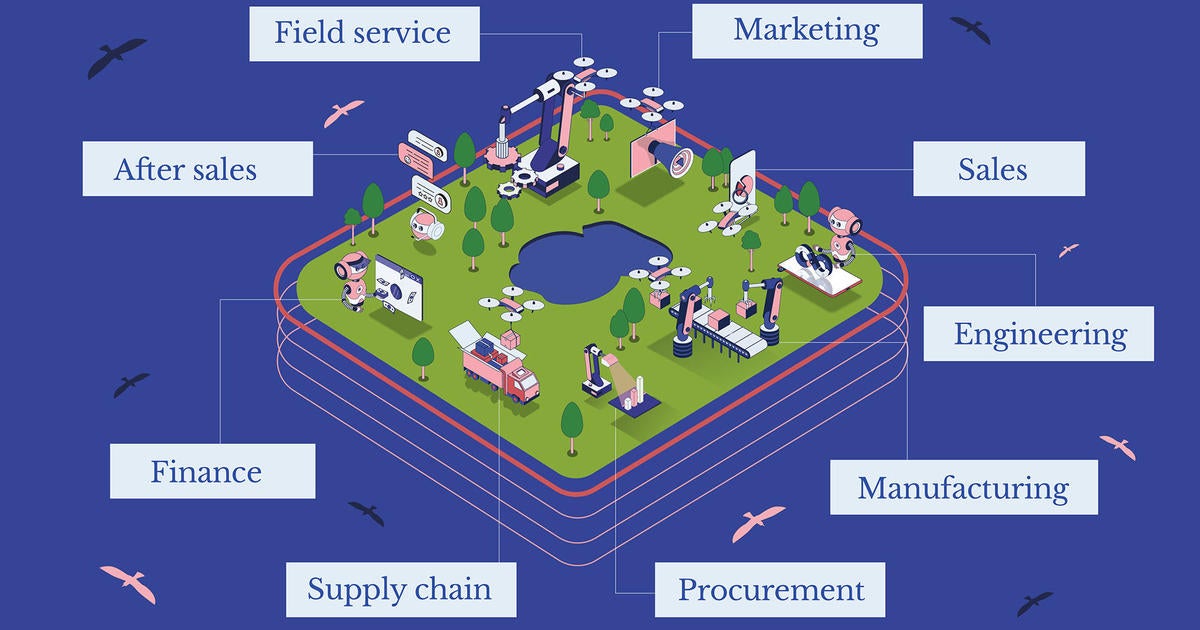

Industry 5.0 represents the next phase in the industrial revolution, characterized by a collaboration between humans and machines. Unlike its predecessor, Industry 4.0, which focused heavily on automation and the Internet of Things (IoT), Industry 5.0 emphasizes the integration of human creativity with advanced technologies. This fusion aims to enhance productivity while addressing societal challenges, including sustainability and personalized customer experiences.

The Role of Digital Infrastructure

The backbone of Industry 5.0 is a robust digital infrastructure. This infrastructure encompasses a range of technologies, from cloud computing and edge computing to advanced data analytics and artificial intelligence (AI). Here’s how these components play a crucial role:

- Cloud Computing: Provides scalable resources and storage solutions that enable businesses to adapt quickly to changing demands.

- Edge Computing: Processes data closer to the source, reducing latency and improving real-time decision-making capabilities.

- Data Analytics: Transforms raw data into actionable insights, empowering businesses to make informed decisions.

- Artificial Intelligence: Enhances automation and enables predictive maintenance, driving efficiency and innovation.

Transformative Technologies Shaping Industry 5.0

Several key technologies are set to transform the landscape of Industry 5.0:

1. Artificial Intelligence and Machine Learning

AI and machine learning are at the forefront of Industry 5.0. By leveraging algorithms that learn from data, businesses can automate processes, predict trends, and enhance customer experiences. For instance, AI-driven chatbots can provide personalized customer service, while machine learning can optimize supply chain logistics.

2. Internet of Things (IoT)

The IoT connects devices and systems, allowing for seamless communication and data exchange. In Industry 5.0, IoT will enable smart factories where machinery monitors itself, reporting potential failures before they occur, thus minimizing downtime and costs.

3. Advanced Robotics

Robots in Industry 5.0 will not just perform repetitive tasks; they will collaborate with human workers to enhance production processes. Cobots (collaborative robots) are designed to work alongside humans, improving efficiency and safety in manufacturing environments.

4. 5G Technology

The rollout of 5G networks will revolutionize connectivity, allowing for faster data transfer and communication between devices. This will enable real-time analytics and decision-making, further enhancing the capabilities of IoT and AI.

Preparing for the Digital Infrastructure Revolution

To prepare for the upcoming changes brought by Industry 5.0, businesses must take proactive steps in developing their digital infrastructure. Here are some strategies to consider:

- Invest in Training and Development: Equip your workforce with the necessary skills to work alongside advanced technologies. Continuous learning programs can help employees adapt to new tools and methodologies.

- Enhance Cybersecurity Measures: As digital infrastructure expands, so do the risks associated with cyber threats. Implement robust cybersecurity protocols to protect sensitive data and maintain customer trust.

- Collaborate with Technology Partners: Partnering with tech firms can provide access to cutting-edge solutions and expertise that may not be available in-house.

- Adopt Agile Methodologies: Embrace flexibility in processes and project management to quickly adapt to changing technologies and market needs.

The Importance of Sustainability in Industry 5.0

As businesses prepare for Industry 5.0, sustainability must be a core focus. The integration of green technologies not only helps in compliance with regulations but also appeals to a growing base of environmentally conscious consumers. Here are some sustainable practices to consider:

- Energy Efficiency: Implement energy-saving technologies and practices in production processes to reduce carbon footprints.

- Circular Economy: Adopt a circular approach to production, focusing on reusing materials and minimizing waste.

- Smart Supply Chains: Leverage IoT and AI to enhance supply chain transparency and efficiency, reducing environmental impact.

Conclusion: Embracing the Future

Preparing for Industry 5.0 is not merely about adopting new technologies; it’s about embracing a holistic approach that integrates human creativity with advanced digital infrastructure. Businesses that prioritize their digital transformation will be better positioned to navigate the complexities of this new industrial era. By investing in the right technologies and practices, organizations can unlock unprecedented levels of productivity and innovation, ensuring their success in the future landscape of Industry 5.0.

In summary, the digital infrastructure revolution is upon us, and those who take the steps necessary to prepare will not only survive but thrive in this exciting new chapter of industrial evolution.

See more Future Tech Daily